TREADMILL MAINTENANCE – TREADMILL DIAGNOSTIC TROUBLESHOOTING |

|||||||||||||||||

| TREADMILL ERRORS | ERROR E1 | ||||||||||||||||

| ERRORS E6, E7 | |||||||||||||||||

| ERRORS E2, E4 | |||||||||||||||||

| MONITOR | |||||||||||||||||

| THE TREADMILL MONITOR DOESN'T TURN ON | |||||||||||||||||

| PROBLEMS WITH THE PULSATIONS | |||||||||||||||||

| THE TREADMILL MONITOR DOES NOT SHOW ANY DATA AT ALL OR ONLY SOME DATA | |||||||||||||||||

| THE MONITOR DOES NOT FINISH START UP OR BEEPS | |||||||||||||||||

| BELT MOVEMENT | TREADMILL SPEED PROBLEMS | ||||||||||||||||

| Non constant. Jerky movement. | |||||||||||||||||

| Accelerates by itself. | |||||||||||||||||

| the belt slows down, stops or the speeds drops when the user steps on it | |||||||||||||||||

| TREADMILL BELT PROBLEMS | |||||||||||||||||

| the belt veers to the right/left. | |||||||||||||||||

| the belt has a fold. | |||||||||||||||||

| the belt stops, but the front roller continues to turn. | |||||||||||||||||

| the belt is worn out. | |||||||||||||||||

| NOISES | BELT | ||||||||||||||||

| Light continued noise coming from the back. | |||||||||||||||||

| Intermittent metallica noise (clack-clack). | |||||||||||||||||

| A ticking or whistling noise | |||||||||||||||||

Treadmill repair tips and spare parts supply. Our shop is specialized in treadmills and stationary bikes' spare parts, such as treadmill belts, drive belts, treadmill motors and controllers. For any information please visit our treadmill parts shop or write to us at treadmillparts@partsfortreadmill.com

Saturday 26 July 2014

treadmill repair guide

Most common treadmill problems repair & troubleshooting guide.

Monday 21 July 2014

STARTRAC TREADMILL DIAGNOSTIC TEST MODES

DISPLAY

TEST MODE

Test the display circuit board by holding

the [5] key down while switching the treadmill on. All

the displays stay lit until a key is pressed, whereupon the software revision number is displayed.

Pressing different keys, other than [STOP], illuminate different patterns on the display.

Pressing [STOP] ends the display board test.

the displays stay lit until a key is pressed, whereupon the software revision number is displayed.

Pressing different keys, other than [STOP], illuminate different patterns on the display.

Pressing [STOP] ends the display board test.

MOTOR

TEST MODE

WARNING: DO NOT RUN ON THE TREADMILL IN MOTOR TEST MODE.

Enter the Motor Test Mode by turning the

treadmill power switch ON with the [8] key depressed.

Alternate LED's in the track display blink twice per second.

Alternate LED's in the track display blink twice per second.

The numeric displays show elevation motor Revolutions

Per Second, speed command num-

ber (SCN) as a number between 3 and 240 and belt speed in km/hr:

ber (SCN) as a number between 3 and 240 and belt speed in km/hr:

ELAPSED

TIME

DISTANCE SPEED

(RPS) (SCN) (km/hr)

-50 45 8.7

(RPS) (SCN) (km/hr)

-50 45 8.7

The Program indicator LED's show the state of various

sensors:

1 "RPM" sensor ON

2 "RPM" sensor ON

3 Elevation sensor ON

4 0% sensor ON

5 "RPM" sensor OFF

6 "RPM" sensor OFF

7 Elevation sensor OFF

8 0% sensor OFF

2 "RPM" sensor ON

3 Elevation sensor ON

4 0% sensor ON

5 "RPM" sensor OFF

6 "RPM" sensor OFF

7 Elevation sensor OFF

8 0% sensor OFF

The [FAST] key increases and the [SLOW]

key decreases the speed command number

(SCN).

(SCN).

The [UP] and [DOWN] keys set the

elevation direction relay when pressed; hold either key for

more than half a second to run the elevation motor.

more than half a second to run the elevation motor.

Use the [LAPS]

key to test the watchdog circuit on the motor

control board, disabling both

motors. The running belt and elevation motors will not operate until power is turned off and re-

started.

motors. The running belt and elevation motors will not operate until power is turned off and re-

started.

The [START] key begins the "Burn-In" program.

Error detection is enabled.

The [O] – [9] number and [DISP]

keys are ignored

The [STOP] key exits to the "CHOOSE

0-9" opening display.

NOTES:

* Elevation

RPS display updates twice per second.

* Downward motion displays with a minus sign.

* Speed display updates ten times per second.

* Downward motion displays with a minus sign.

* Speed display updates ten times per second.

The [UP] and [DOWN] keys

switch the direction relay immediately, even if the elevation motor

is moving. The motor does not stop automatically on the zero percent switch. Changing direction

while elevation is running should be avoided.

is moving. The motor does not stop automatically on the zero percent switch. Changing direction

while elevation is running should be avoided.

Except during "Burn-In", the

unit will not detect elevation errors, but will detect all

"CPU Errors" and "SPd Error 1".

"CPU Errors" and "SPd Error 1".

VOLTAGE COMPENSATION ADJUSTMENT

STARTRACS are all pre-adjusted at the factory to cover a wide range of line voltages However,

there are cases where the incoming power to a facility are out of the voltage compensation ran ge

of the STARTRAC. If the incoming voltage is too low, a "SPd Error 2" will be displayed. If the volt -

age is too high, the STARTRAC will run faster than 1 MPH ( 2 km/hr On metric systems) when

commanded to minimum speed

there are cases where the incoming power to a facility are out of the voltage compensation ran ge

of the STARTRAC. If the incoming voltage is too low, a "SPd Error 2" will be displayed. If the volt -

age is too high, the STARTRAC will run faster than 1 MPH ( 2 km/hr On metric systems) when

commanded to minimum speed

For optimal performance of the STARTRAC, check the voltage compensation after initial assembly and whenever the symptoms listed above occur. The procedure is as follows:

A. Switch off main power.

B. Enter motor test mode by holding down the [8] key while switching on power to the

treadmill.

treadmill.

NOTE With the exception of speed, the displays in motor test mode indicate functions

differing from those labeled on the panel.

differing from those labeled on the panel.

DO NOT STAND ON THE RUNNING BELT WHEN PERFORMING THE STEPS BELOW:

C. The center numerical display reflects a speed command value. Initially, this value should

be the number 3 (minimum command). The running belt should be at a stop. If not, VR2

on the motor control board must be adjusted (see location diagram). With a small

be the number 3 (minimum command). The running belt should be at a stop. If not, VR2

on the motor control board must be adjusted (see location diagram). With a small

screwdriver, slowly adjust VR2 counter-'clockwise just until the belt stops.

D. Set the command to 18 using the [FAST] key to increase ([SLOW] to decrease). Verify

that the running belt moves at least 1" (25.4 mm) per second. If not, adjust VR2 in the

clockwise direction until it does.

that the running belt moves at least 1" (25.4 mm) per second. If not, adjust VR2 in the

clockwise direction until it does.

E. Return the command to 3 using the [SLOW] key to decrease. If the belt is not at a stop,

repeat steps (C) through (E).

repeat steps (C) through (E).

F. Exit motor test mode either pressing the [STOP] key or switching main power off.

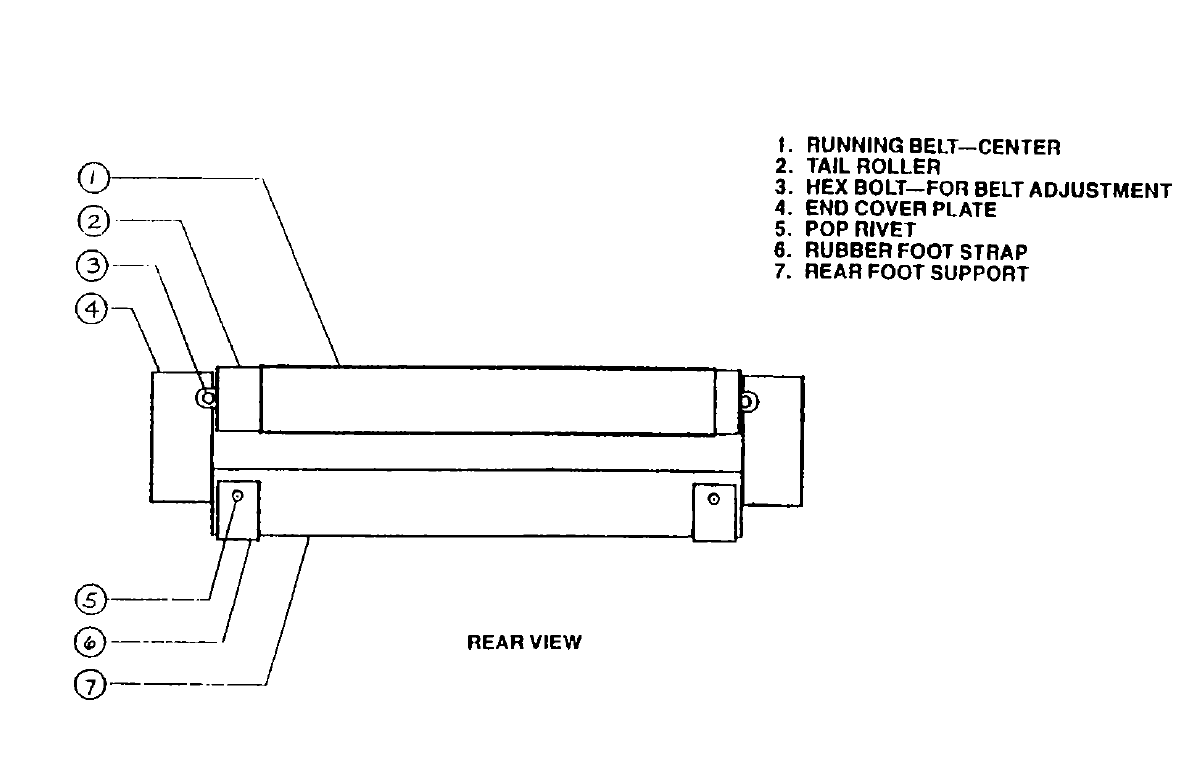

BELT ADJUSTMENTS

RUNNING BELT

Belt tracking adjustments may become necessary. The adjustment bolts are at the tail roller

and require a 1/4" (6.35mm) Hex Key Drive. Turning the right bolt clockwise will cause the belt

to move to the left and vice versa. Adjust one bolt only half a turn at a time. Run the belt slowly

at 2-3 MPH (3-5 km/hr) while adjusting, then run it fast for 30 seconds or more to check the result.

Adjust the belt to ride in the center of the running surface and motor shroud.

and require a 1/4" (6.35mm) Hex Key Drive. Turning the right bolt clockwise will cause the belt

to move to the left and vice versa. Adjust one bolt only half a turn at a time. Run the belt slowly

at 2-3 MPH (3-5 km/hr) while adjusting, then run it fast for 30 seconds or more to check the result.

Adjust the belt to ride in the center of the running surface and motor shroud.

MOTOR BELT

The motor drive belt might require tensioning during normal use. Adjust the motor belt tension

to eliminate slippage. The adjusting procedure is as follows:

to eliminate slippage. The adjusting procedure is as follows:

Unplug the unit, unscrew and lift the motor shroud. Loosen the motor bolts and tension bolt

lock nut. Turn the tension bolt 1/4 turn clockwise. Tighten tension bolt lock nut and motor bolts.

Position the motor shroud and plug the unit in.

lock nut. Turn the tension bolt 1/4 turn clockwise. Tighten tension bolt lock nut and motor bolts.

Position the motor shroud and plug the unit in.

ELEVATION BELT

We designed and engineered the elevation belt and pulley assembly for years of trouble free

use; however, if the belt and assembly needs servicing or if you hear a "popping" noise when

using the elevation system proceed as follows:

use; however, if the belt and assembly needs servicing or if you hear a "popping" noise when

using the elevation system proceed as follows:

1. Elevate the treadmill to a 10% grade.

2. Unplug the unit, lift the motor shroud and place a piece of carpet or other soft material

next to the equipment.

3. Carefully tip the unit on its side and inspect the belt tension. A 1/4" (8mm) deflection with

moderate pressure is acceptable.

4. If more tension is necessary, loosen the 1/2" (12.7mm) bolt retaining the idler pulley

assembly. Increase the tension to a 1/4" (6mm) deflection by moving the idler pulley.

5. Tighten the 1/2" (12,7mm) idler assembly bolt.

6. Return the unit to an upright position, plug it in and check the operation of the elevation

mechanism. If it's working satisfactorily, unplug the power cord, lower and position the

motor shroud and reinsert the plug.

2. Unplug the unit, lift the motor shroud and place a piece of carpet or other soft material

next to the equipment.

3. Carefully tip the unit on its side and inspect the belt tension. A 1/4" (8mm) deflection with

moderate pressure is acceptable.

4. If more tension is necessary, loosen the 1/2" (12.7mm) bolt retaining the idler pulley

assembly. Increase the tension to a 1/4" (6mm) deflection by moving the idler pulley.

5. Tighten the 1/2" (12,7mm) idler assembly bolt.

6. Return the unit to an upright position, plug it in and check the operation of the elevation

mechanism. If it's working satisfactorily, unplug the power cord, lower and position the

motor shroud and reinsert the plug.

RUNNING BED

The phenolic material laminated running bed surface is coated with a "wax-like" substance.

During the break-in period, (20-30 hrs. of operation), this material may "migrate" along the sur-

face of the running bed and accumulate on the head and tail rollers: This accumulation could

cause a slight "thumping" noise. If the thumping noise persists after a prolonged period of time,

you should remove some of the accumulation from the tail roller. The procedure is as follows:

During the break-in period, (20-30 hrs. of operation), this material may "migrate" along the sur-

face of the running bed and accumulate on the head and tail rollers: This accumulation could

cause a slight "thumping" noise. If the thumping noise persists after a prolonged period of time,

you should remove some of the accumulation from the tail roller. The procedure is as follows:

1. Turn the belt adjustment bolts counter-clockwise with the 1/4" (8.35mm) Hex Key Driver

far enough to loosen the running belt.

far enough to loosen the running belt.

2. Remove the largest accumulations of the "wax-like" material, DO NOT remove all the

substance, as it is needed to lubricate the running bed and belt.

substance, as it is needed to lubricate the running bed and belt.

3. Turn the belt adjustment bolts clockwise and adjust the belt to ride in the center of the

running surface and motor shroud. DO NOT over tighten, as this will distort the shape

of the running belt.

running surface and motor shroud. DO NOT over tighten, as this will distort the shape

of the running belt.

BELT ADJUSTMENTS

RUNNING BELT

Belt tracking adjustments may become necessary. The adjustment bolts are at the tail roller

and require a 1/4" (6.35mm) Hex Key Driver. Turning the right bolt clockwise will cause the belt

to move to the left and vice versa. Adjust one bolt only half a turn at a time. Run the ban slowly

at 3-5 km/hr while adjusting, then run it fast for 30 seconds or more to check the result. Adjust

the belt to ride in the center of the running surface and motor shroud.

and require a 1/4" (6.35mm) Hex Key Driver. Turning the right bolt clockwise will cause the belt

to move to the left and vice versa. Adjust one bolt only half a turn at a time. Run the ban slowly

at 3-5 km/hr while adjusting, then run it fast for 30 seconds or more to check the result. Adjust

the belt to ride in the center of the running surface and motor shroud.

MOTOR BELT

The motor drive belt might require tensioning during normal use. Adjust the motor belt tension

to eliminate slippage. The adjusting procedure is as follows:

to eliminate slippage. The adjusting procedure is as follows:

Unplug the unit and lift the motor shroud. Loosen the motor bolts and tension bolt lock nut.

Turn the tension bolt 1/4 turn clockwise. Tighten tension bolt lock nut and motor bolts. Position

the motor shroud, and plug the unit in.

Turn the tension bolt 1/4 turn clockwise. Tighten tension bolt lock nut and motor bolts. Position

the motor shroud, and plug the unit in.

ELEVATION BELT

We designed and engineered the elevation belt and pulley assembly for years of trouble free

use; however, if the belt and assembly needs servicing or if you hear a "popping" noise when

using the elevation system proceed as follows:

use; however, if the belt and assembly needs servicing or if you hear a "popping" noise when

using the elevation system proceed as follows:

1. Elevate the treadmill to a 10% grade.

2. Unplug the unit, lift the motor shroud and place a piece of carpet or other son material

next to the equipment.

next to the equipment.

3. Carefully tip the unit on its side and inspect the belt tension. A 6mm deflection with

moderate pressure is acceptable.

moderate pressure is acceptable.

4. If more tension is necessary, loosen the 1/2" (12.7mm) bolt retaining the idler pulley

assembly. Increase the tension to a 6mm deflection by moving the idler pulley.

assembly. Increase the tension to a 6mm deflection by moving the idler pulley.

5. Tighten the 1/2" (12.7mm) idler assembly bolt.

6. Return the unit to an upright position, plug it in and check the operation of the elevation

mechanism. If it's working satisfactorily, unplug the power cord, lower and position the

motor shroud and reinsert the plug.

mechanism. If it's working satisfactorily, unplug the power cord, lower and position the

motor shroud and reinsert the plug.

RUNNING BED

The phenolic material laminated running bed surface is coated with a "wax-like" substance.

During the break-in period, {20-30 hrs. of operation), this material may "migrate" along the

surface of the running bed and accumulate on the head and tail rollers. This accumulation could

cause a slight "thumping" noise. If the thumping noise persists after a prolonged period of time,

you should remove some of the accumulation from the tail roller. The procedure is as follows:

During the break-in period, {20-30 hrs. of operation), this material may "migrate" along the

surface of the running bed and accumulate on the head and tail rollers. This accumulation could

cause a slight "thumping" noise. If the thumping noise persists after a prolonged period of time,

you should remove some of the accumulation from the tail roller. The procedure is as follows:

1. Turn the belt adjustment bolts counter-clockwise with the 1/4" (6.35mm) Hex Key Driver

far enough to loosen the running belt.

far enough to loosen the running belt.

2. Remove the largest accumulations of the "wax-like" material. DO NOT remove all the

substance, as it is needed to lubricate the running bed and belt.

substance, as it is needed to lubricate the running bed and belt.

3. Turn the belt adjustment bolts clockwise and adjust the belt to ride in the center of the

running surface and motor shroud DO NOT over tighten, as this will distort the shape

of the running belt.

running surface and motor shroud DO NOT over tighten, as this will distort the shape

of the running belt.

ERROR MESSAGES

STARTRAC Displays Error Messages when the computer detects a malfunction. Please

record the Error Type AND Number displayed. This information, along with the definition of

Error Messages in the troubleshooting section, will tell the repair person what to do.

record the Error Type AND Number displayed. This information, along with the definition of

Error Messages in the troubleshooting section, will tell the repair person what to do.

Error messages can be cleared only by switching off power to the treadmill.

For service, contact us or visit www.partsfortreadmill.com.

CPU ERROR

If STARTRAC detects a fault in its internal operations it will stop and display "CPU Error 0 or

1 or 2" (Probably caused by turning the treadmill OFF and ON too quickly - the microprocessor

is not reset and also trips the circuit watchdog). Turn the power switchOFF, wait a couple of

seconds and then turn the power switch ON If the problem occurs again, contact Unison for assistance.

1 or 2" (Probably caused by turning the treadmill OFF and ON too quickly - the microprocessor

is not reset and also trips the circuit watchdog). Turn the power switchOFF, wait a couple of

seconds and then turn the power switch ON If the problem occurs again, contact Unison for assistance.

ELEVATION ERROR

If a problem develops with the elevation mechanism, "El Error 0, 1, 2 or 3" is displayed and the

treadmill stops.

treadmill stops.

Possible causes of this error include a stalled elevation motor, a defective elevation sensor or

cable, or a defective zero percent sensor or cable.

cable, or a defective zero percent sensor or cable.

To allow operation of the treadmill until elevation can be serviced, depress the [0] key while

switching the machine on. In this mode, "EL-OFF' will appear for several seconds at power up

and no elevation operations will occur.

switching the machine on. In this mode, "EL-OFF' will appear for several seconds at power up

and no elevation operations will occur.

FAIL-SAFE ERROR

If the microprocessor detects the fail-safe (watchdog) circuit tripped on the motor control board

at the start or during a run, the display will show "FS Error O". Possible causes for this are cycling

power too fast (see CPU ERROR), defective motor control board or defective display cable.

at the start or during a run, the display will show "FS Error O". Possible causes for this are cycling

power too fast (see CPU ERROR), defective motor control board or defective display cable.

SPEED ERROR

The display reads "SPEED Error 0, 1, or 2" when the microprocessor detects a problem with

the motor speed control.

the motor speed control.

THIS MAY SHOW AN UNSAFE CONDITION

Possible causes are a defective or misadjusted motor speed sensor / cable or motor control

board.

board.

Thursday 17 July 2014

Treadmill repair in UK

Treadmill Maintenance & Repair Service

Customer notice

Treadmill Parts provides to Customers contacts of qualified service engineers within UK. Treadmill repair service is provided by independent treadmill service centers. For information or suggestions please contact service@treadmillsrepair.co.uk

You can get the contacts of qualified treadmill service engineers at the following link

Treadmill maintenance and repair UK

Service engineers notice

If you want to be listed, please contact service@treadmillsrepair.co.uk

Friday 4 July 2014

FITNESS EQUIPMENT SERVO MOTOR SYSTEM TROUBLESHOOTING

Item

|

Breakdown

|

Troubleshooting

|

1

|

LCD

no display.

|

1. Make sure the Adaptor have plug in the AC electrical outlet properly..

2. Make sure the Adaptor’s electrical socket have

plug in the stage. Check whether it

bad contact or not.

3. Check the Adaptor’s AC voltage ,to see if it

is same as the user’s household

voltage.

4.Check the console together with the stage’s

12PIN connect cable, to see if the

console are bad contact or get loose with the

stage’s 12PIN connect cable.

5. Check the DC JACK 3PIN connect cable are

loose or not.

|

2

|

No alteration of resistance

|

1. When the LOAD/LEVEL is up or down, to see the Motor is running or not .

2.Check the console together with the stage’s

12PIN connect cable, to see if the console are bad contact or get loose with

the stage’s 12PIN connect cable.

3. To see the Motor is running or not after plug in the adaptor again and

turn on the console.

|

3

|

NO Hand pulse figure display

|

1. Make sure the user holds both hands on the handgrip sensor. Please keep both hands together at the same tame on handpulse, during training

period.

2. Check the signal cable which in the handgrip sensor, to see if it loose or not.

3. To see the console whether in the low-speed

(energy saving mode) or not.

|

4

|

No display of Built-in figure

|

1. Make sure user have wear the built-in belt in the proper position. Make

sure the body is abreast with the console.

2. Check the battery is is dead or not, please changes the battery and tests

it again.

3. To see the console whether in the low-speed

(energy saving mode) or not.

|

5

|

LCD display error E-1

|

1.E-1 is indicate the console have not receive

the body fat figure , Make sure the user have hold onto the handgrip sensor ,Please

do hold two hands together during training period.

|

6

|

LCD display error E-4

|

1.

E-4 is indicate the user’s age, height, weight

figure have exceed of the setting range when user setting their information.

please according the use’s actual figure setting your information.

|

7

|

LCD display error E-2

|

1.Check the console together with the stage’s

12PIN connect cable, to see if the

console are bad contact or get loose with the stage’s 12PIN connect cable.

2. Check the Motor distance have exceed of

the setting range or not.

|

8

|

No display of SPEED figure

|

1.

Check the console together with the stage’s

12PIN connect cable, to see if the

console are bad contact or get loose with the stage’s 12PIN connect cable

2. Check

the Speed SENSOR cable, to see if it is bad contact or getting loose.

|

9

|

Fail to respond the RECOVERY function.

|

1 Check the console is in the STOP condition or not.

2. Check the pulse function, to see if it

can display the pulse figure or not.

|

If you need spare parts or assistance, please contact us

Subscribe to:

Posts (Atom)